Mechanical Seals For Petrochemical Industry

Quantech sealing Seals pumps, and valves keep central processes running safely, professionally and with the operational flexibility required to grow with every day demand in petrochemical plants all over the world.

We are the leading manufacturer and supplier of Mechanical seals for petrochemical industry in India and around the world, the transport medium of rotating equipment is usually high temperature, high pressure, flammable, explosive, toxic and harmful fluid, and its reliability is particularly important. Mechanical seal has been widely used because of the advantages, such as high reliability, good interchangeability, simple structure and compact structure, convenient maintenance and so on. We need to analyze the seal structure, material and flushing, and choose the suitable petrochemical mechanical seal for the pump, so as to improve the reliability of the seal. Compared with single face mechanical seal, double face mechanical seal is suitable for strong corrosion, suspended particles, flammable, explosive and volatile medium. When sealing high-pressure medium, the pressure difference at each end of each seal can be allocated reasonably, and the working pressure range of the seal can be improved. In petroleum industry, double face mechanical seal is a good choice.

What type of Mechanical Seals used for Petrochemical Industry?

Mechanical seals are fundamental to the reliable operation of the pumps used in chemical plants. It’s critical to agree the right configurations and construction materials to maximize equipment uptime. With our expertise in metallurgy and therefore the application of sophisticated mechanical sealing technologies, we excel in extending mean solar time between failures (MTBF) of critical rotating equipment in challenging petrochemical applications.

Featured mechanical seals include:

- QB high-pressure, single-cartridge pusher seals

- BX high-pressure, single-cartridge metal bellows seals

- ISC2-PX (pusher) and ISC2-BX (bellows) standard cartridge seals

- HSH high-pressure, high-speed pusher seals

High corrosion resistance, energy efficiency, and high-temperature and high-pressure performance are critical for pumps in petrochemical applications. QMS offers the industry’s widest selection of proven pump types during a full range of materials and hydraulics to maximize performance and minimize lifecycle costs.

Petrochemical mechanical seal for the pump

Chemical processes, particularly cracking boilers in ethylene production units, require valves capable of handling large input streams at extremely high temperatures and pressures with precision control and reliability. These valves must also resist corrosion from chemical feeds like acid gas removal systems. Quantech seals offers an entire range of valves and actuation products to suit the diverse applications found in chemical and petrochemical plants.

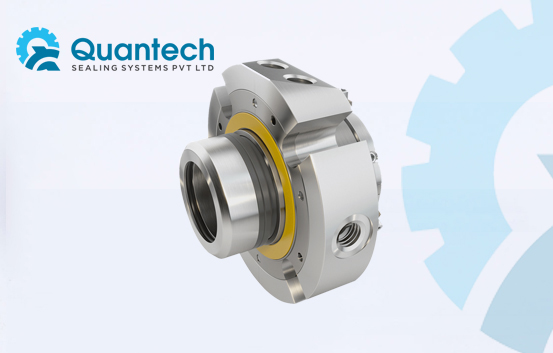

Use of a Double Cartridge Seal allows the containment of clean fluid between the sets of faces. this products are proven, rugged performers in a wide range of sealing applications across industries. double Cartridge seals are ideal for plant-wide standardization and save time with easy installation. Chesterton’s cartridge seal offerings include exclusive, patented features such as self-centering lock rings and adjustable gland tabs.

Specification Of Double Cartridge Seal

- Seal Characteristics : Double acting, Double Cartridge, Double seal with dual balanced, Inside mounted

- Application: Water pump, Chemical, Power, Pharma, Refinery

- Face Material : Carbon, Tungsten carbide, Silicon carbide, Ceramic

- Metal Parts: SS316,SS304 Secondary Seal :Elastomers ,PTFE

- Operating Limits : Shaft Dia:12mm to 125mm, Pressure : 15 bar(max), Temp:- 20 to 220 deg C